At the heart of the toner vs ink cartridges debate lies a fundamental difference in materials: toner is a fine, dry powder for laser printers, while ink is a liquid for inkjet printers. This distinction changes everything.

For a business that cranks out high volumes of text documents, like a law firm printing contracts, toner is almost always the winner for speed and cost-effectiveness. But if you’re a real estate agent printing vibrant, photo-quality marketing materials, ink is your go-to. This isn’t just a minor technical detail—it directly impacts your upfront costs, long-term budget, and even workflow efficiency.

Making the Right Choice for Your Office

Choosing between a laser printer (which uses toner) and an inkjet (which uses ink) is a bigger decision than it seems. It’s a choice that ripples through your office’s budget, productivity, and the final quality of your documents. The low sticker price on an inkjet printer can be tempting, but the true cost reveals itself over time in the price you pay per page. For example, a small business might buy a $100 inkjet printer, only to realize they’re spending $60 every month on ink, while a $300 laser printer might only require an $80 toner cartridge every six months.

This guide goes beyond the surface-level differences. We’ll break down the factors that really matter in a business setting, looking at the initial hardware investment and, more importantly, the ongoing expense of consumables.

Key Decision Factors

Before you invest in new hardware, you need to align the technology with how your office actually operates. Think through these key points:

- Print Volume: How many pages is your team printing each month? A small accounting firm printing 5,000 invoices a month has very different needs than a creative agency printing 200 client proofs. If you’re running a high-volume operation, the efficiency of toner is hard to beat.

- Document Type: What are you printing? If it’s mostly text-heavy contracts, reports, and internal memos, laser is your workhorse. If you need rich, high-resolution color for photos or marketing slicks, inkjet is king.

- Speed Requirements: Is print speed a bottleneck in your workflow? In a busy medical office, waiting ten minutes for a 50-page patient file to print on an inkjet is a huge delay. A laser printer could handle it in just over a minute.

- Longevity and Storage: Do you stock up on supplies? Toner has an incredible shelf life, while liquid ink cartridges can dry out over time, leading to waste. A school that buys supplies for the entire year in August will find its toner is perfectly fine in May, but its spare ink cartridges might be clogged.

These business realities are reflected in the global printer consumables market. The ink and toner cartridge market was valued at USD 19.116 billion in 2023 and is expected to climb to USD 33.703 billion by 2032. Much of this growth is fueled by the laser printer segment, prized for its efficiency in offices and schools. For more details, you can explore some of the latest ink and toner cartridges industry trends.

The Bottom Line: That inexpensive inkjet printer can become a serious operational expense when you factor in the high cost of ink. On the flip side, a laser printer’s higher upfront cost is often recovered through its much lower cost-per-page.

Getting a handle on these foundational differences is the first step toward making a smart investment. Let’s dive deeper to help you pick the right technology for your company’s needs.

Toner vs Ink a Quick Comparison for Businesses

To get started, here’s a scannable summary of the fundamental differences between toner and ink. This table gives you a high-level overview before we dive into the nitty-gritty details.

| Feature | Toner (Laser Printers) | Ink (Inkjet Printers) |

|---|---|---|

| Printing Material | Dry plastic powder | Liquid dye or pigment-based ink |

| Best For | High-volume text, sharp documents, and business reports | High-resolution photos and detailed color graphics |

| Cost Per Page | Lower, especially for monochrome printing | Higher, particularly for color documents |

| Print Speed | Significantly faster | Slower, especially for high-quality prints |

| Shelf Life | Very long (years if stored correctly) | Shorter (can dry out or expire within 1-2 years) |

| Initial Cost | Higher printer cost | Lower printer cost |

This at-a-glance view helps frame the conversation, but the real value comes from understanding how these differences play out in real-world business scenarios.

How the Technology Actually Works

To make sense of the toner vs ink cartridges debate, you have to look past the plastic shells and get to the core technology. The way each one puts an image on paper is fundamentally different, and that difference dictates everything—speed, quality, cost, and reliability. We’re not just talking about powder versus liquid; we’re talking about two completely different printing philosophies.

Toner cartridges are the lifeblood of laser printers, and their process is all about precision and stability. It’s a surprisingly elegant dance of static electricity and heat that’s incredibly effective for office work.

The Science of Toner and Laser Printing

A laser printer works through a multi-step process that’s built for consistency and speed. It all starts with a laser beam “drawing” an invisible, negatively charged version of your document onto a positively charged drum. This creates a perfect electrostatic blueprint.

Next, the toner—a very fine powder of plastic and pigment—is rolled onto that drum. Because the toner is also positively charged, it only sticks to the negatively charged areas drawn by the laser. It’s this incredibly precise method that gives laser-printed text its signature sharpness.

Finally, the paper rolls past the drum, picking up the powdered image. It then passes through a fuser, which is just a pair of hot rollers. The heat melts the plastic particles in the toner, permanently bonding the image to the fibers of the paper.

This fusing step is why pages come out of a laser printer warm to the touch and are instantly dry and smudge-proof. If you’re in a busy law firm printing contracts that need to be highlighted right away, that kind of reliability is everything.

The Mechanics of Ink and Inkjet Printing

Ink cartridges work on a much simpler principle: they power inkjet printers by spraying microscopic droplets of liquid ink directly onto the page. You can think of it like a highly controlled spray-painting process, using thousands of tiny nozzles to build your document or photo.

Inkjet printers generally use one of two methods to get the ink from the cartridge to the paper:

- Thermal Inkjet: This is the most common approach, used by brands like HP and Canon. A tiny resistor inside the print head heats up, vaporizing a bit of ink. This creates a bubble that expands and pushes a droplet of ink out of the nozzle.

- Piezoelectric Inkjet: Epson is the primary user of this method. It involves a crystal that physically changes shape when an electric current hits it, creating a pressure pulse that squeezes a droplet of ink out.

This liquid-based system is exactly why inkjet printers are masters of color blending, making them the go-to choice for printing photos and graphics with subtle gradients. A marketing agency printing a glossy brochure for a client, for example, needs the rich, vibrant colors that only an inkjet can deliver.

Of course, this reliance on liquid ink is also its biggest weakness. The ink can smudge if you touch it before it dries completely, and if you don’t use the printer regularly, the nozzles can clog. This leads to frustrating cleaning cycles and wasted ink, which is a major reason why toner often wins out in demanding business settings.

Analyzing Cost Performance and Print Quality

When you’re looking at the true cost of a printer, the sticker price is just the tip of the iceberg. The real expenses pop up over time with the supplies you have to buy again and again. This is where the toner vs. ink cartridges debate really matters for any business’s bottom line.

It’s easy to get lured in by a cheap inkjet printer, but that initial savings can quickly evaporate once you start buying ink. To get the full picture, you need to dig into the numbers—specifically, the cost per page, print speed, and how many pages you get out of a single cartridge. These metrics tell the real story of which technology gives you the best bang for your buck.

Deconstructing the Cost Per Page

The single most important number to look at is the cost per page (CPP). It’s a straightforward calculation: just divide the price of the cartridge by its page yield. This simple formula cuts through the marketing and reveals the true long-term cost.

Let’s run a quick, real-world scenario. A high-yield toner cartridge might set you back $120, but it can print around 3,000 pages. Do the math, and your CPP is a lean 4 cents per page. Now, look at a standard ink cartridge. It might only cost $40, but you’ll be lucky to get 400 pages out of it. That pushes the CPP up to 10 cents per page.

For an office printing 2,000 pages a month, that difference is stark. The laser printer would cost $80 in toner, while the inkjet would cost $200 in ink. Over a year, that’s a savings of $1,440 simply by choosing the right technology.

This is exactly why laser printers and toner are the workhorses in most offices. Even with newer tech like ink tank printers entering the scene, toner’s combination of low running costs and sheer reliability is hard to beat for high-volume jobs. The global market reflects this, with ink and toner generating USD 36.46 billion in 2026 and projected to hit USD 51.89 billion by 2035. Toner’s value is propped up by its impressive page yields, often between 3,000-10,000 pages, compared to ink’s typical 200-500. As you can imagine, that higher yield also means surplus OEM toner has a much better resale value. You can dive deeper into the printer cartridge market dynamics to see how these trends are shaping up.

To help you visualize the key differences, here’s a detailed breakdown of the most important metrics.

Detailed Breakdown of Cost and Performance Metrics

| Metric | Toner Cartridge (Laser) | Ink Cartridge (Inkjet) |

|---|---|---|

| Upfront Cost | Higher initial printer cost | Lower initial printer cost |

| Cost Per Page (Text) | Very Low (typically 2-5 cents) | High (typically 7-12 cents) |

| Cost Per Page (Color) | Moderate (10-15 cents) | Very High (often 20+ cents) |

| Page Yield | Very High (1,500 – 10,000+ pages) | Low (200 – 800 pages) |

| Print Speed (PPM) | Fast (20-100+ pages per minute) | Slow (5-20 pages per minute) |

| Best Use Cases | High-volume text, reports, internal documents, invoices | High-resolution photos, marketing materials, low-volume color printing |

This table makes it clear: if your priority is cost-effective, high-volume printing, toner is the undisputed champion. For specialized, high-quality color work, ink still holds its ground.

Speed and Yield: A Productivity Comparison

Cost isn’t everything; time is money, too. A slow printer can create a frustrating bottleneck, especially when your team is trying to get large reports out the door.

- Print Speed (Pages Per Minute – PPM): Laser printers are built for speed. Even basic models start at 20-30 PPM, and office-grade machines can easily push past 40-50 PPM. Best of all, they maintain that speed whether you’re printing one page or a hundred. Inkjets are much slower, usually clocking in at 5-15 PPM for standard quality documents.

- Page Yield: As we’ve covered, this is toner’s home run. A higher yield doesn’t just save money; it means you’re swapping out cartridges far less often. For instance, an office assistant might have to replace an ink cartridge weekly, while a toner cartridge could last for months. That’s less downtime, less hassle ordering supplies, and more time for your team to focus on their actual work.

Print Quality for Specific Document Types

The question of “which is better” for print quality really depends on what you’re printing. Each technology has its own strengths.

Toner uses a dry powder that’s fused to the paper with heat. The result is incredibly sharp, crisp text that won’t smudge or run, even if it gets wet. This makes it perfect for any professional document where clarity and durability are key.

Ink, being a liquid, is fantastic at blending colors. It can create the subtle gradients and deep, saturated tones needed for photorealistic images. The trade-off is that the ink needs a moment to dry and can be prone to smudging right after printing.

Here’s a quick guide to choosing the right tech for the job:

| Document Type | Recommended Technology | Why It Excels |

|---|---|---|

| Financial Reports & Invoices | Toner (Laser) | Delivers razor-sharp text and fine lines, ensuring readability and professionalism. |

| Contracts & Legal Documents | Toner (Laser) | Creates permanent, smudge-proof prints that are ideal for archiving and handling. |

| Marketing Brochures & Flyers | Ink (Inkjet) | Produces vibrant, high-resolution color graphics and photorealistic images. |

| High-Volume Internal Memos | Toner (Laser) | Offers the lowest cost per page and fastest speed for bulk text-based printing. |

| Client Photo Proofs | Ink (Inkjet) | Achieves superior color accuracy and smooth gradients essential for photography. |

So, while an inkjet printer might look like a great deal on the shelf, a laser printer almost always wins on total cost of ownership in a busy office, delivering a potent mix of speed, efficiency, and professional-grade text.

Shelf Life and Inventory: A Critical Business Factor

When you’re managing office supplies, longevity isn’t just a minor detail—it’s a critical factor that hits your bottom line. In the toner vs ink cartridges debate, the difference in shelf life is one of the most significant, yet often overlooked, distinctions. This is about more than just avoiding waste; it’s about protecting the value of your inventory and making sure your assets don’t expire on the shelf.

The core reason for this difference comes down to what each one is made of. Toner is essentially a dry, stable polymer powder. Think of it like fine dust. Since there are no liquids, it’s incredibly resistant to aging.

The Durability of Toner

If you store an original (OEM) toner cartridge correctly—in a cool, dry place, out of the sun—it can last for years. Its components simply don’t evaporate or dry out. This makes toner perfect for businesses that like to buy in bulk to get better pricing.

Imagine an office manager finds a box of sealed OEM toner cartridges during a storeroom cleanout. Even if they’re two or three years old, they are almost certainly good to go. That stability protects your initial investment and means the cartridges can be used or sold as surplus without any problems.

The resilience of toner is a key reason why it’s favored in environments with fluctuating print needs. A cartridge purchased for a project that gets delayed will still be ready to go months or even years later.

For items like toner and ink, understanding the best practices for inventory management is essential. Proper storage and tracking help you optimize stock, cut costs, and get the maximum value from your supplies.

The Fragility of Ink

Ink cartridges, on the other hand, are a completely different story. Ink is a liquid—a mix of dyes, pigments, and chemicals suspended in water—which makes it fundamentally less stable. Even when sealed in its original packaging, an ink cartridge is fighting against time.

- Evaporation: The liquid base can slowly evaporate through microscopic pores in the packaging, which thickens the ink and ruins print quality.

- Clogging: Over time, pigments can settle and separate, creating a sludge that clogs the tiny nozzles in the printer’s printhead. This is a classic cause of streaky prints or missing colors.

- Air Bubbles: Tiny air bubbles can form as the ink ages, disrupting the ink flow and causing inconsistent printing.

This inherent instability is why most ink cartridges have a “use by” date, usually 18-24 months from when they were made. A two-year-old sealed ink cartridge is a gamble. It might work, but there’s a good chance it will be useless or even damage your printer. This reality directly impacts asset recovery, as surplus buyers have much stricter standards for ink, often requiring at least a year of shelf life remaining.

Market forecasts underscore toner’s superior long-term value, with laser technology driving growth in commercial printing. The global ink and toner market, which hit USD 30.13 billion in 2025, is expected to reach USD 40.25 billion by 2032. Toner’s segment continues to shine, partly because laser technology boasts 99% uptime, whereas inkjet clogs can affect 20-30% of units in humid climates. This long-term reliability makes toner a more stable and predictable asset for any business managing its inventory.

Matching the Right Printer to Your Business Needs

Figuring out the whole toner vs ink cartridges debate really comes down to looking at how your business actually operates. Forget the spec sheets for a minute. The best printer is the one that fits your daily workflow, budget, and what you’re actually printing. Let’s move past the generic advice and look at some real-world business scenarios to make this choice crystal clear.

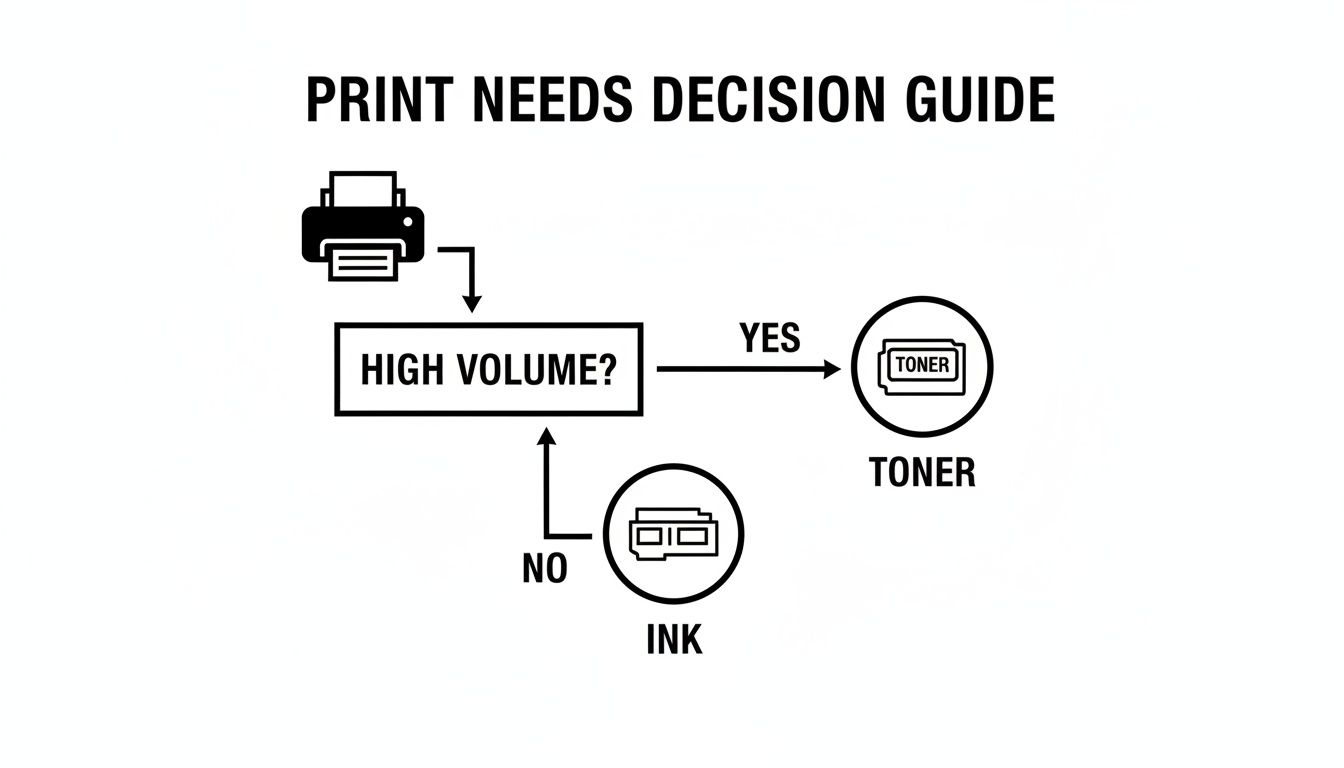

This simple decision guide gets right to the heart of the matter: how much printing do you really do?

As you can see, there’s a pretty clear line in the sand. If high-volume printing is your world, toner is almost always the answer. For more specialized, lower-volume needs, ink comes into play. This is the first question you need to answer to get on the right track.

The High-Volume Text Environment

Picture a law firm, an accounting practice, or a busy logistics company. These places run on paper. They churn out thousands of pages of text-heavy documents every single month—contracts, invoices, shipping manifests, you name it. For them, printing can’t be an afterthought; it’s a core operational function.

In this kind of setting, a monochrome laser printer using toner is the undisputed champion. It’s built for exactly this kind of work.

- Lowest Cost-Per-Page: At just a few cents a page, toner keeps high-volume printing from blowing up your budget.

- Superior Speed: When you need to print a 50-page contract, you want it in a minute, not ten. A laser printer keeps things moving and prevents those frustrating bottlenecks at the printer.

- Document Permanence: The heat-fused toner creates sharp, smudge-proof documents that are perfect for signing or long-term archiving.

For businesses like these, the higher initial price of a laser printer pays for itself surprisingly quickly through massive savings on consumables. It’s a smart long-term investment.

The Creative and Client-Facing Business

Now, let’s switch gears and think about a marketing agency, a real estate office, or a graphic design studio. Here, printed materials are a direct reflection of their brand. They need to create a powerful visual impression with vibrant, high-fidelity color for presentations, property brochures, and design proofs.

This is where an inkjet printer using ink cartridges really shines. Its ability to flawlessly blend colors and produce deep, saturated tones is exactly what you need for photorealistic quality. The slower print speed and higher cost-per-page are acceptable trade-offs because the quality of the final product is what truly matters.

Key Insight: The decision isn’t just about cost; it’s about purpose. A law firm would find an inkjet’s running costs painfully high, while a marketing agency would find a laser printer’s color output just doesn’t cut it for their creative work.

The Hybrid Small Business Scenario

So, what about a growing small business with a little bit of everything? They print a lot of internal reports and invoices but also need to produce the occasional color flyer or marketing handout. It’s a common dilemma that calls for a smart, balanced solution.

There are two great ways to tackle this:

- The Color Laser Printer: This is an excellent compromise. You get the speed and cost-effectiveness of a laser printer for everyday black-and-white jobs, plus good-quality color for marketing materials. It might not have the same photo-quality pop as a high-end inkjet, but it’s more than enough for most professional business graphics.

- The Dual-Printer Strategy: Many businesses find this is the most effective approach. You get a workhorse monochrome laser printer to handle all the heavy lifting (invoices, reports), and a less expensive inkjet that’s reserved specifically for high-quality color jobs.

This two-printer approach often ends up being the most cost-effective in the long run, ensuring you never have to compromise on speed or quality. For businesses that go this route, managing different types of supplies becomes part of the routine. Knowing how to handle and even liquidate surplus inventory is a key skill for an efficient operation. You can get more information on how to manage surplus printer supplies from experienced dealers.

Cashing In on Your Surplus Toner and Ink Cartridges

It happens to every business. You upgrade your printers, move offices, or someone just orders the wrong model. Suddenly, you’re stuck with a stockpile of perfectly good, unused printer supplies taking up valuable space. For example, a company might upgrade from an old HP LaserJet to a new model, leaving them with five boxes of unused toner for the old machine.

Don’t let those boxes of toner and ink collect dust. They’re a hidden asset you can easily turn back into cash. Finding a reputable buyer who specializes in surplus supplies makes the process simple and helps you recover some of that invested capital. You’d be surprised how much value is sitting on those shelves.

First, Take Inventory

Before you can get a quote, you need a clear picture of what you have. A simple list or spreadsheet is all it takes.

For each box of toner or ink, jot down these details:

- Brand: HP, Brother, Canon, etc.

- Model Number: This is the most important part (e.g., HP 87A or CF287A).

- Quantity: How many of each specific cartridge do you have?

- Box Condition: Are the boxes still factory-sealed? Note any damage, writing, or opened seals.

Once you have your list, getting a quote is usually quick and painless. You can often go from creating your inventory to having an offer in hand within a few hours.

What Do Buyers Look For?

Legitimate buyers have clear acceptance standards to make sure they’re getting usable products. While the exact rules can differ, a few things are universal.

The Golden Rule of Resale: Your cartridges must be genuine Original Equipment Manufacturer (OEM) products. That means they were made by the same company that made the printer. Buyers almost never accept third-party or compatible cartridges.

The condition of the packaging is also a huge factor. The boxes need to be factory-sealed and in reasonably good shape—no major rips, water damage, or heavy writing.

For ink cartridges, the expiration date is critical. Because ink is a liquid, it has a much shorter shelf life than toner. Most buyers will only accept ink that has at least one year of life left before its expiration date. This is one of the biggest differences in the toner vs ink cartridges resale market and really highlights how well toner holds its value over time.

Ready to see what your surplus supplies are worth? You can easily submit your toner inventory list online for a competitive offer. Companies specializing in this often cover the shipping with prepaid, insured labels, so there’s no cost to you. Once they receive and inspect your items, payment is sent out quickly, turning that forgotten clutter into useful cash for your business.

Frequently Asked Questions

When you’re trying to figure out the whole toner vs. ink cartridge debate, a few common questions always seem to pop up. Let’s clear the air on some of the most frequent ones so you can make a confident choice for your business.

Can I Refill My Own Toner or Ink Cartridges?

You technically can, but in a professional setting, it’s a huge gamble. Trying to refill ink cartridges yourself is messy business and often ends with leaks that can completely ruin your printer.

Refilling toner is even trickier. You’re dealing with a superfine plastic powder that’s not something you want to breathe in, and it requires specialized tools to do it right. Beyond the mess and health risks, using non-OEM refills almost always voids your printer’s warranty. You’ll likely see worse print quality, get fewer pages than you expect, and risk damaging critical parts like the drum or fuser. For any business that can’t afford downtime, sticking with genuine OEM cartridges is the only way to go.

Will Toner Dry Out if I Don’t Print Often?

Nope, toner won’t dry out. It’s a dry powder, which gives it an incredibly long shelf life. A toner cartridge can sit on a shelf or in a printer for years and work perfectly on the first print.

This makes laser printers a fantastic choice if you don’t print every day. For instance, a small business that only prints invoices at the end of the month will find a laser printer ready to go every time. You can leave the machine off for weeks or even months and trust it will work when you need it. Ink, on the other hand, is a liquid that dries out, especially with infrequent use. This leads to clogged printheads, wasted ink from constant cleaning cycles, and replacing pricey cartridges that are still half full.

Key Takeaway: If your printing is sporadic, a laser printer is a far more reliable and cost-effective investment. You completely sidestep the frustration and expense of dried-out ink.

Is Toner Bad for the Environment?

Both toner and ink cartridges create e-waste if they aren’t handled properly. The real story is a bit more complex, though. A single toner cartridge can print thousands of pages—often 10 to 20 times more than a standard ink cartridge.

Think about it: over the life of your printer, you’ll be buying, using, and throwing away far fewer toner cartridges. That means less plastic waste and a smaller carbon footprint from manufacturing and shipping. Plus, major brands like HP, Canon, and Brother have excellent recycling programs for their OEM toner. For a deeper dive into managing and disposing of cartridges, our comprehensive FAQ page provides more detailed answers.

Ready to turn your surplus printer supplies into cash? At Toner Connect LLC, we make it simple to sell your unused, genuine OEM toner and ink cartridges. Get a fast, competitive quote and free, insured shipping to convert that excess inventory back into working capital.