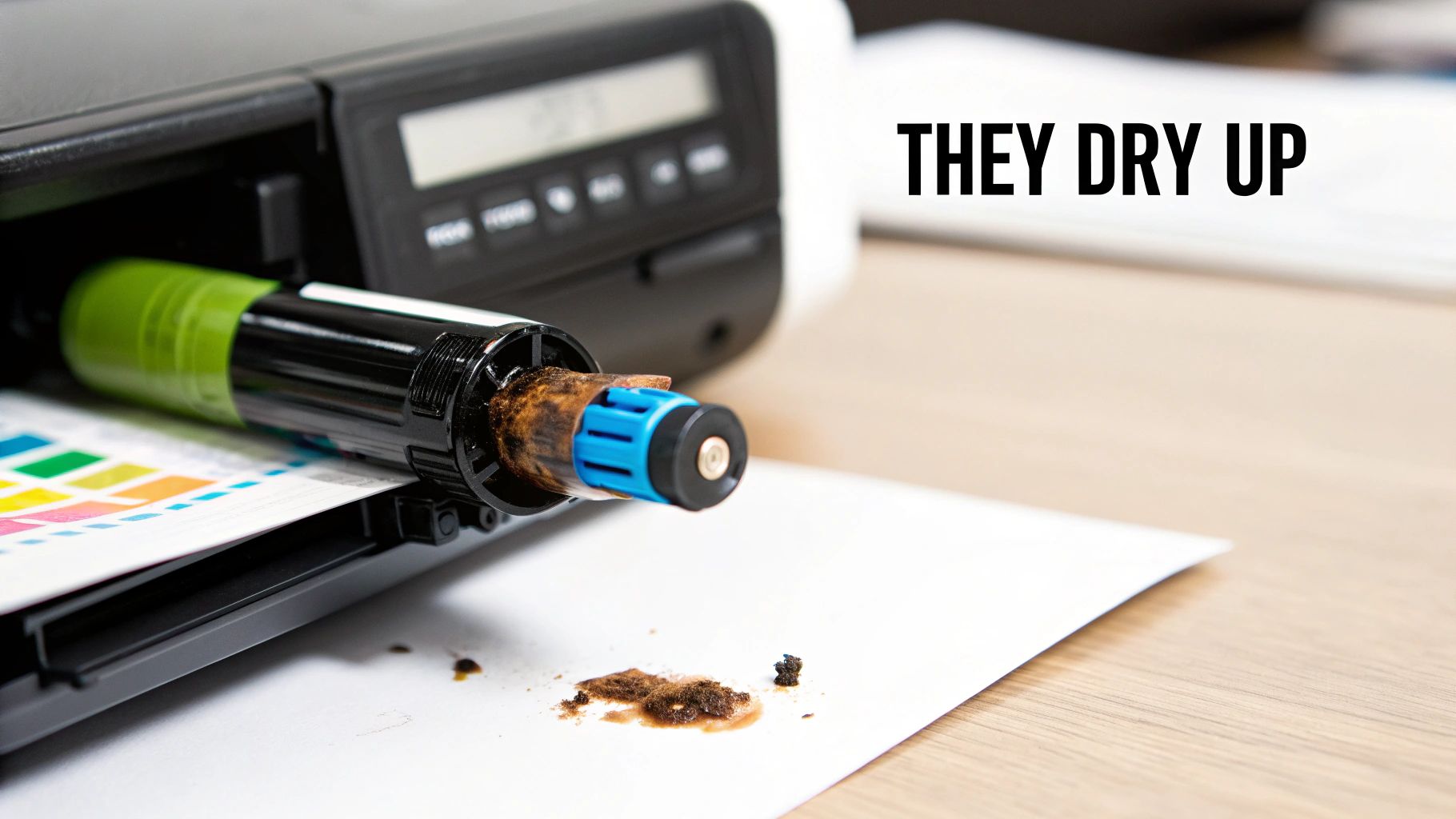

Yes, ink cartridges absolutely dry up. It's one of crushes, the most common and frustrating problems for anyone with an inkjet printer.

Think of it like leaving the cap off a felt-tip marker. When the liquid ink is exposed to air, it starts to evaporate, leaving behind a thick, sludgy pigment that just can’t flow. If you only print a shipping label once a month, you're almost guaranteed to run into this.

Ever come back to your printer after a few weeks, only to be greeted by streaky, faded, or completely blank pages? That’s the classic sign of a dried-out cartridge. The root of the problem is simple: air is the enemy of liquid ink.

When a cartridge sits unused, the water or solvent that gives the ink its fluid consistency slowly evaporates. For example, if you go on a two-week vacation and leave your printer idle, that’s plenty of time for air to start thickening the ink. This process creates a two-pronged headache for your printer:

This isn't just a minor annoyance; it's a significant technical challenge that affects printer reliability everywhere. With the global ink cartridge market projected to be worth around USD 21.8 billion in 2025, finding ways to manage this common issue is a big deal for everyone. You can find more insights about the ink cartridge market on futuremarketinsights.com.

To get ahead of the problem, it helps to know what you’re up against. The table below breaks down the most frequent reasons your ink dries out and gives you a straightforward way to prevent each one.

| Cause | What Happens | Best Prevention Strategy |

|---|---|---|

| Infrequent Printing | Ink sits stagnant in the printhead, giving air plenty of time to evaporate the liquid components. Example: You only print concert tickets every few months. | Print a single color test page at least once a week to keep things flowing. |

| Improper Storage | Exposure to heat, direct sunlight, or very low humidity speeds up the evaporation process significantly. Example: Storing spare cartridges in a hot garage or on a sunny windowsill. | Store spare cartridges upright in their sealed packaging in a cool, dark, and dry place. |

| Incorrect Shutdown | The printhead isn't properly "parked" and capped, leaving the delicate nozzles exposed directly to air. Example: Turning off the power strip your printer is plugged into instead of using the printer's power button. | Always turn the printer off using its dedicated power button, never the power strip. |

| Expired Cartridges | The ink's chemical stabilizers can break down over time, making it much more prone to separating and clogging. Example: You find an old cartridge from a previous printer model and try to use it. | Always check the expiration or "install by" date before opening and installing a new cartridge. |

Understanding these key culprits is the first step toward getting consistent, high-quality prints and avoiding the frustration of a clogged-up machine.

Ever left the cap off a marker pen only to find it dry and useless the next day? The same exact thing happens to your printer's ink cartridges, just on a much more precise, microscopic level. It's all about keeping the ink wet until the moment it hits the paper.

Printer ink is more than just colored water. It’s a complex chemical cocktail, a mix of colorants (like dyes or pigments) suspended in a liquid base, usually water combined with other solvents. This liquid vehicle is designed to carry the color and flow perfectly through the printhead.

The trouble begins with evaporation. Once exposed to air, the liquid starts to evaporate, leaving behind the thick, sludgy colorants. This is the root cause of the problem and the simplest answer to the question: do ink cartridges dry up? Absolutely, and as the ink thickens, it can no longer squeeze through the tiny nozzles of the printhead.

Drying out isn't just a matter of time passing; the environment surrounding your printer plays a huge role. Several factors can put the evaporation process into overdrive and cause premature clogging.

Think of these environmental factors as working together to create a hostile environment for your ink.

For example, a cartridge in a climate-controlled office at 70°F (21°C) with stable humidity might be fine for months, even with infrequent use. That same exact cartridge, if stored in a hot, dry garage over the summer, could start clogging up in just a matter of weeks.

This thickening process inevitably leads to the ultimate headache: a clogged printhead. A printhead is an incredible piece of engineering, packed with hundreds or even thousands of nozzles, each one smaller than a human hair.

When that thickened ink sludge tries to pass through these microscopic channels, it gets stuck and forms a solid plug. At first, you might just notice some streaking or faded spots in your prints. For example, a line of text might have white gaps running through it. If you ignore it, that blockage can become permanent, making the cartridge—and sometimes the entire printer—completely useless. This is why keeping that ink from evaporating is so critical to maintaining good print quality and getting the most out of your supplies.

The best way to stop your ink cartridges from drying out boils down to one simple idea: treat them right. This applies whether they're sitting in your printer or waiting in a supply closet. A little proactive care is the best defense you have for protecting your investment and making sure the ink is ready to go when you are.

The good news? Proper storage is surprisingly easy. You don't need any fancy equipment, just a bit of know-how about what keeps ink happy. Let's walk through the best practices for both your spare, unopened cartridges and the ones you already have installed.

When you've got spare cartridges on hand, the golden rule is to leave them in their original, factory-sealed packaging. That vacuum-sealed foil or plastic wrapper is your cartridge's best friend—it's engineered to keep air out and prevent the evaporation that dries up the ink.

The moment you break that seal, the countdown begins. To get the most out of every spare, just follow these simple guidelines:

By sticking to these rules, a sealed OEM cartridge can easily last until its expiration date, which is typically around 24 months. On the other hand, just a little bit of mishandling can slash that lifespan dramatically.

For the cartridges that are already in your printer, the game plan changes from storage to active maintenance. Here, the best defense is a good offense, which really just means using your printer often enough to keep the ink flowing.

The single most effective thing you can do is print something—anything—at least once a week. It doesn't need to be a 10-page report. A simple test page with a bit of black and some color is all it takes to push fresh ink through the nozzles, clearing out any gunk before it has a chance to harden. A great practical example is setting a weekly calendar reminder to print a recipe or a puzzle for your kids. Think of it as a quick jog for your printer; it prevents the ink from stagnating and clogging the delicate printhead. For more great advice, you can explore the Toner Connect blog for guides on managing your printer supplies effectively.

Here’s a quick cheat sheet to help you remember the do's and don'ts of ink cartridge storage:

| Action | Best Practice (The "Do") | Common Mistake (The "Don't") |

|---|---|---|

| Location | Store cartridges in a climate-controlled closet or desk drawer. | Don't leave them near a sunny window or a heating vent. |

| Packaging | Keep spare cartridges in their original sealed packaging until use. | Don't open a new cartridge just to have it "ready" to go. |

| Orientation | Always store cartridges in an upright position. | Don't toss them into a box where they can lie on their side. |

| Usage | Print a test page at least once every week. | Don't let your printer sit completely idle for several weeks or months. |

That moment of frustration is universal: you go to print an important document, and the page comes out streaky, faded, or completely blank. It’s the tell-tale sign of a dried or clogged ink cartridge. Before you toss it in the trash, take a breath. You can often get that stubborn cartridge working again with a few simple tricks, starting with the easiest ones first.

Your printer itself has a built-in first-aid kit for this very problem. Every inkjet printer has a printhead cleaning cycle you can run from its software or control panel. This feature essentially forces a small burst of ink through the nozzles to break up any minor blockages. For example, on an HP printer, you would open the HP Smart app, select your printer, go to "Printer Quality Tools," and choose "Clean Printheads."

You may need to run the cycle two or three times to fully clear the clog. Just be mindful that each cycle uses up a bit of ink, so don't go overboard. If a few tries don't improve the print quality, it’s time to roll up your sleeves for a more direct approach.

For clogs that are a little more persistent, the damp paper towel trick is a go-to. It’s gentle, safe, and surprisingly effective. The idea is simple: use warm moisture to soften the dried, crusty ink that's blocking the printhead.

Of course, the best fix is prevention. Here's a quick reminder of how to store your ink correctly to avoid this issue altogether.

Keeping cartridges sealed until you need them and storing them upright in a cool spot is your best defense against drying out.

To try the paper towel revival:

Crucial Warning: Be very careful to avoid touching the shiny, copper-colored electronic circuitry on the cartridge. The oils on your fingers can easily disrupt the connection to the printer and lead to frustrating "cartridge not recognized" errors.

If a gentle dab doesn't do the trick, you're likely dealing with a more serious blockage. It's time for a soak. Grab a shallow dish and some distilled water. It's absolutely critical to avoid tap water for this; the minerals can cause permanent damage and clog the printhead even worse.

Here’s what to do:

Most of the time, one of these methods will break up the clog and get your ink flowing freely again.

Before you start, it helps to know what you're getting into. Some methods are safer and easier than others, while some are a last-ditch effort.

| Method | Effectiveness | Risk Level | Best For |

|---|---|---|---|

| Printer's Cleaning Cycle | Low-Moderate | Very Low | Minor clogs or routine maintenance |

| Damp Paper Towel | Moderate | Low | Light to moderate clogs; great first step |

| Warm Water Soak | High | Medium | Stubborn or severe clogs |

| Isopropyl Alcohol | Very High | High | Extreme blockages (Last resort only) |

Ultimately, choosing the right method depends on how bad the clog is. Always start with the lowest-risk option and only move on to more aggressive techniques if the simpler ones fail.

It’s a classic office scenario: you upgrade your printers or change your printing setup, and suddenly you're stuck with a supply closet full of brand-new ink cartridges that don't fit a single machine you own. For example, your company replaces all its HP OfficeJet printers with a new fleet of Canon models, leaving you with 50 unusable HP 952 cartridges. Tossing them feels even worse.

But there’s a much better option. Instead of letting that inventory become a complete loss, you can sell your surplus supplies. Specialized buyback companies exist for this exact reason—they purchase these unused cartridges from businesses like yours, turning what would have been waste into working capital.

This is the most direct solution for a problem almost every business runs into eventually. It’s a smart move to get some money back on your initial investment and, just as importantly, free up that precious storage space.

When you're ready to sell, you'll find that buyback companies have a pretty specific checklist. Knowing what they're looking for ahead of time will make the whole process go smoothly. It really all boils down to quality and authenticity.

Here’s what a reputable buyback service will almost always require:

This strict focus on quality isn't just arbitrary; it’s about making sure the next person who buys that cartridge gets a product that works perfectly, right out of the box.

The economic impact of dried-out ink is significant. With the global printer ink cartridge market valued at USD 14.97 billion in 2023, every expired or unusable cartridge contributes to waste. Annually, the average consumer can waste 15-25% of their cartridge investment due to drying.

If you're dealing with a large volume of surplus cartridges, proper storage is key while you figure out the sale. For a big inventory, it might even be worth looking into secure business storage facilities to keep your investment safe from temperature swings or damage.

Once you’ve confirmed your cartridges tick all the boxes—they're OEM, sealed, and have plenty of time before they expire—the rest is easy. At Toner Connect, we've made the process of getting a quote and getting paid as simple as possible. You can head over to our site to sell your unused surplus ink cartridges and quickly turn that dead stock back into cash for your business. It's a win-win: you recover funds, and perfectly good products stay out of the landfill.

So, do ink cartridges dry out? Absolutely. It’s not some weird tech mystery; it’s just basic physics. The liquid that carries the color in your ink is designed to evaporate, and over time, it will—leaving you with a gunky mess and a printer that refuses to work. But that doesn't mean you have to be a victim of dried-up ink.

With a little bit of foresight, you can make sure your printer is ready to go whenever you need it. It all comes down to building a few good habits.

Think of these tips as your go-to defense against printing headaches and wasted cash. They’re dead simple, but they make a world of difference.

Sticking to these small routines is a game-changer. You stop reacting to problems like a dried-out cartridge and start preventing them altogether. This saves you a ton of frustration and the $30 to $60 it costs to replace the average cartridge.

But smart management isn't just about the ink you're using. It's also about what you do with the supplies you're not. If your company upgrades its printers, don't let those surplus OEM cartridges become expired, useless plastic in a supply closet.

Selling your sealed, genuine cartridges is a brilliant financial move. It helps you recoup your initial investment, keeps usable products out of landfills, and clears out clutter all at once. It’s the final piece of the puzzle for managing your printing costs effectively.

Even with the best plan, you're bound to run into specific questions about ink. Let's tackle some of the most common ones that pop up, giving you quick, clear answers to save you some money and a lot of frustration.

Think of a brand-new, factory-sealed ink cartridge like a canned good. It's protected. It typically has a shelf life of around two years, and you'll usually find an expiration date printed right on the box.

But once you pop that seal and install it, the clock starts ticking a whole lot faster. The real-world lifespan of an installed cartridge comes down to its environment and how often you're actually printing.

If it's sitting in a climate-controlled office and you print every week, that cartridge should be fine right up until the ink runs out. Take that same cartridge and leave it in a hot, dry room for a few weeks without use, and you're practically inviting it to clog. This is exactly why a little bit of printing on a regular basis is so important once a cartridge is installed.

The answer to "do ink cartridges dry up?" changes dramatically once they're opened. A sealed cartridge is protected, but an installed one is in a constant battle against air exposure and evaporation.

Ink tank printers are definitely more resilient against drying out than their cartridge-based cousins, but they aren't totally bulletproof. Their design—with airtight ink reservoirs and sealed delivery systems—is a huge advantage because it dramatically slows down evaporation. For this reason, they're a fantastic choice if you don't print very often.

That said, even an ink tank printer can end up with a clogged printhead if you let it sit idle for months on end. For example, if you store an Epson EcoTank printer for six months without use, you'll still likely need to run several cleaning cycles to get it working properly again. The core principle doesn't change: ink is a liquid that needs to flow. For more detailed answers on different printer types and their quirks, you can always check our comprehensive printer supply FAQ page.

Yes, this is a huge one. It's absolutely critical to always use the printer's own power button to turn it off. Never just unplug it or kill the power with a surge protector switch.

When you press that power button, you're kicking off the printer's official shutdown sequence. This process is designed to move the printhead back to its "parked" or "capped" station, which creates a seal over the incredibly fine nozzles. Think of it as putting a lid back on a marker. This one simple action makes a massive difference in preventing the ink from drying out and causing the clogs we’ve been talking about.

If you're tired of watching your unused ink supplies lose value, Toner Connect can help. We buy surplus, unopened OEM ink and toner cartridges, turning your excess inventory back into cash. Request your free quote today