Toner cartridge manufacturing is a $4.5 billion global industry. Yet, only 20 to 30 percent of toner cartridges are recycled, making the recycled toner market worth roughly $1 billion.

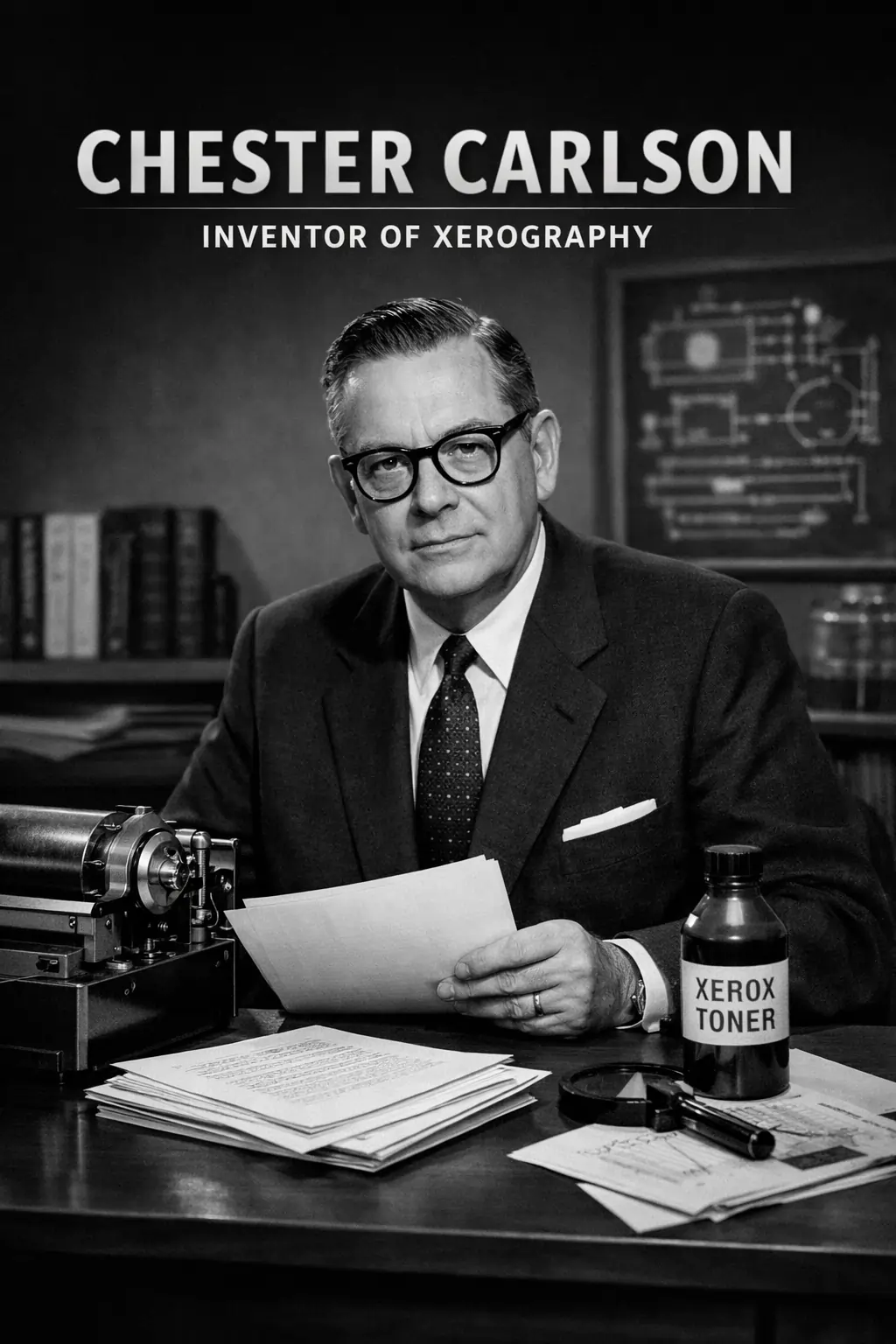

“The need for a quick, satisfactory copying machine that could be used right in the office seemed very apparent to me—there seemed such a crying need for it—such a desirable thing if it could be obtained. So I set out to think of how one could be made.”

— Chester Carlson, Copies in Seconds

Today, toner buyers are beginning to ask critical questions:

-

How did the toner cartridge market come to be?

-

Where is the industry headed?

-

Who is influencing the market—and why?

A toner cartridge sent to landfill can take up to 1,000 years to degrade. Each year, over 350 million toner cartridges end up in landfills—enough to cover 100 standard-sized football fields.

Even more concerning, toner cartridge manufacturing grows by 12 percent annually.

If that growth rate continues, the environmental burden will escalate rapidly. In the United States alone, 70 percent of non-recycled toner cartridges contribute to this problem.

Recycling toner cartridges not only benefits the planet—it can reduce printing costs by up to 50 percent compared to OEM cartridges.

So how did the toner cartridge begin, and where is it headed?

The Evolution and Future of the Toner Cartridge Industry

Chester Carlson invented xerography in 1938. Also known as electrophotography, the process used electrostatic charges to produce dry copies and was initially applied to book reproduction and office copying.

In 1959, Xerox introduced the Xerox 914, transforming Carlson’s invention into the foundation of modern laser printing.

The Xerox 914 was complex, expensive, and required trained technicians. The machine could even overheat and catch fire, which is why every unit was shipped with a fire extinguisher—a concept unimaginable today.

The name “914” came from its ability to copy paper measuring 9 by 14 inches.

The toner used in the Xerox 914 was made from carbon, plastic polymers, and iron oxide—materials still used in modern toner cartridges, albeit with refinements.

Early Toner Cartridge Designs and Their Complexity

The earliest toner cartridge was a fixed box inside the Xerox 914. It could be refilled but not replaced, requiring toner to be poured through a special opening.

Technicians faced numerous challenges, including:

-

Toner dust spills

-

Respiratory health risks

-

Combustible toner dust explosions

Toner dust explosions occurred when fine toner particles became suspended in air and reacted with oxygen.

In addition to toner, the developer unit—a medium that carried toner—also required frequent refilling. The process was inefficient, labor-intensive, and wasteful.

Apple, HP, Canon, and the Toner Cartridge Revolution

Canon initially developed the LBS-10 print engine, followed by the Canon CX. Lacking computer expertise, Canon partnered with Apple and Hewlett-Packard (HP).

Xerox declined collaboration through its subsidiary, Diablo Data Systems. Meanwhile, Xerox released the Xerox Star 8010, a powerful but prohibitively expensive office printer.

Canon and HP capitalized on this opportunity, launching the HP LaserJet in 1984. Priced at $3,500, the HP LaserJet sold over 50 million units in 16 years.

Canon took advantage of the high price of the Xerox Star 8010. The Japanese company collaborated with HP to introduce the HP LaserJet in 1984. The revolutionary printer sold for $3,500 at the time and in 16 years sold over 50 million units. Canon provided HP with the Canon CX print engine used in the HP LaserJet.

The printer offered groundbreaking features:

-

8 pages per minute

-

300 dpi print resolution

-

Compact desktop design

-

Lower noise levels

-

Lower cost than competitors

This marked the beginning of the modern toner cartridge economy.

How the HP LaserJet Defined the Modern Toner Cartridge

The HP LaserJet introduced the self-contained toner cartridge, eliminating the need for technicians.

Each toner cartridge included:

-

Toner reservoir

-

Waste toner collector

-

Developer

-

Roller

-

Hopper

Users could simply replace the cartridge when it ran out.

Benefits of the Modern Toner Cartridge

-

No servicing fees

-

Cleaner operation

-

Easy user replacement

-

Elimination of dust explosions

-

Reduced health risks

Competitors like Brother followed suit, creating user-friendly printers with easily replaceable components.

Why Toner Cartridge Recycling Is the Future

While the toner cartridge solved printing challenges, it created serious environmental concerns.

Each year, discarded toner cartridges consume:

-

3.5 billion liters of oil

-

33.6 million kilograms of aluminum

-

126 million kilograms of plastic

Approximately 70 to 80 percent of used toner cartridges still end up in landfills.

Additional environmental impacts include:

-

A single mono toner cartridge releases 4.8 kg of CO₂ during manufacturing

-

16 metric tons of greenhouse gases are emitted per metric ton of toner produced

-

A cartridge takes 1,000 years to degrade

Globally, toner cartridge recycling rates remain at 20–30 percent, compared to 45 percent paper recycling in the U.S. Platforms such as Toner Connect are helping close the recycling gap by making remanufactured toner cartridges more accessible to businesses of all sizes.

Toner Cartridge Remanufacturing and Market Growth

Toner cartridge recycling is difficult for small users due to qualification requirements for collection programs.

However, remanufacturing is rapidly growing.

According to the International Imaging Technology Council:

-

Over 10,000 companies in 85 countries participate

-

105 million cartridges are remanufactured annually

-

84,000 tons of materials are diverted from landfills

-

Market share ranges from 10 to 50 percent, depending on cartridge type

Remanufactured toner cartridges cost up to 50 percent less than OEM cartridges.

Toner Cartridge vs. Inkjet: Cost Comparison

Manufacturing a single toner cartridge shell requires three liters of oil.

Inkjet ink, by comparison, is among the most expensive liquids in the world:

-

Ink costs up to $5,500 per liter

-

Chanel No. 5 perfume: $3,180 per liter

-

Dom Pérignon Champagne: $284 per liter

-

Petrol: $1.48 per liter

This makes toner printers significantly more cost-effective than inkjet printers.

The Future of the Toner Cartridge Industry

Toner cartridges present manageable environmental challenges. Remanufactured cartridges reduce costs, conserve resources, and lower emissions.

While manufacturing continues to grow at 12 percent annually, the shift toward recycling and remanufacturing is accelerating.

The future of the toner cartridge industry depends on increased adoption of sustainable practices—and informed buyers choosing recycled alternatives. By supporting remanufactured toner cartridges and working with platforms like Toner Connect, businesses can lower costs while helping protect the planet.