Ever wonder what makes a family photo pop with color while a business report looks so sharp and clean? It all comes down to the ink. At its core, most printers use one of two main types of printer ink: dye-based inks, which are fantastic for vibrant colors, or pigment-based inks, known for their incredible durability and crisp text.

Think of printer ink like an artist's paint set. Some paints are like watercolors—thin, translucent, and they soak right into the paper. That's your dye-based ink. Others are more like oil paints—thicker particles of color that sit right on top of the canvas. That’s your pigment-based ink.

This single difference—soaking in versus sitting on top—changes everything, from how a print looks to how long it will last. Understanding what's actually inside that little cartridge is a game-changer whether you're managing office supplies, printing your own artwork, or just trying to get the best-looking prints from your home setup.

We'll start by breaking down the two workhorses of the industry—dye and pigment. From there, we'll get into the more specialized inks you see in commercial printing. Getting a handle on these concepts helps you buy smarter and really appreciate the tech behind every page you print. For anyone managing office inventory, this knowledge is even more valuable when it comes to turning surplus supplies into cash.

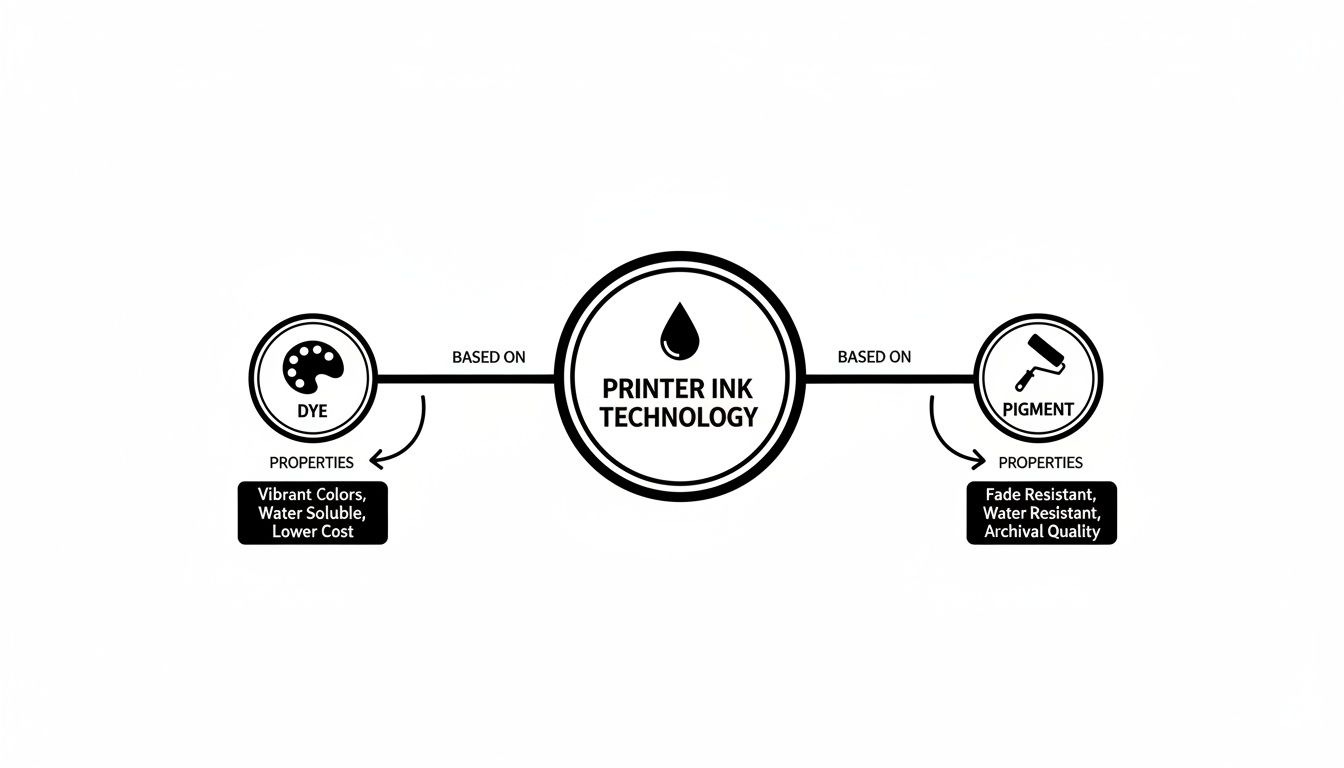

This image gives you a great visual for how these two main ink types work at a microscopic level.

As you can see, it really boils down to a choice: do you want vibrant color that soaks into the page, or do you need sharp, durable text that rests on the surface?

Matching the right ink to the right job is the secret to getting professional results and avoiding waste. If you get it wrong, you end up with faded photos or documents that smudge at the slightest touch. For a business, the stakes are even higher.

In short, the ink inside a cartridge is more than just colored liquid; it's a sophisticated chemical formulation designed for a specific purpose. Knowing the difference between the main types of printer ink is the first step toward mastering your printing needs.

On the surface, all printer ink looks pretty much the same. But when you get down to it, the two most common types—dye-based and pigment-based—are fundamentally different. It's not just marketing speak; their chemical makeup dictates everything from how vibrant your photos look to whether a document will survive a coffee spill.

Getting a handle on this difference is the first step to mastering your prints, whether you're creating a family photo album or printing out a crucial business contract.

The easiest way to think about it is with a simple kitchen analogy. Dye-based ink is like sugar dissolving in water. The color (the sugar) becomes one with the liquid, creating a completely uniform solution.

Pigment-based ink, on the other hand, is more like mixing fine sand in water. The tiny solid particles of color (the sand) don't actually dissolve. They just hang suspended in the liquid. This one simple difference changes everything.

When your printer lays down dye-based ink, that colored liquid soaks right into the paper's fibers. Because it absorbs so deeply, it creates stunningly rich and brilliant colors that almost seem to glow from inside the page. This is exactly why it's the undisputed champion for printing on glossy photo paper.

Real-world example: Think about a photo of a brilliant sunset. A dye-based ink will saturate the glossy paper, making the reds and oranges pop with a depth and vibrancy that feels true to life. The colors just melt into each other seamlessly.

But that very same quality—its ability to absorb—is also its greatest weakness.

The bottom line: Dye-based ink is your go-to for high-impact photos and visuals where jaw-dropping color is the priority. It shines on glossy paper but won't hold up well against moisture or long-term light exposure.

Pigment ink works in the complete opposite way. Instead of soaking in, those microscopic solid particles of color are laid down right on top of the paper. They bond to the surface, creating a solid, durable layer of ink. This "sitting on top" method is the secret to its strengths.

Real-world example: Now, imagine you're printing a legal document or an invoice. That crisp, sharp text you want comes from pigment-based black ink. The edges of every letter are perfectly defined because the ink isn't bleeding or feathering into the paper fibers. And if you do spill something on it, the text is far less likely to smudge once it's dry.

This surface-level application is what gives pigment ink its legendary staying power. The solid pigment particles aren't water-soluble, so they hold up against moisture. Even better, their chemical structure is far more stable, making them incredibly resistant to fading from UV light and even airborne pollutants.

This incredible fade resistance is why professionals rely on pigment inks for archival prints—often called giclée prints. A fine art print made with high-quality pigment inks on archival paper can last for over 100 years without any noticeable color shift. It’s the gold standard for artists and photographers who sell their work.

Here's a cool twist: many modern inkjet printers don't make you choose. They use a clever hybrid system to give you the best of both worlds. It's very common for a printer to use a pigment-based black ink cartridge for durable, razor-sharp text, right alongside a set of dye-based color cartridges for vibrant photos. A practical example is the Canon PIXMA series, where the large "PGBK" black cartridge is pigment for text, while the smaller color cartridges (and a photo black) are dye-based for images. This setup makes a single machine incredibly versatile.

To break it all down, here's a quick cheat sheet:

| Feature | Dye-Based Ink | Pigment-Based Ink |

|---|---|---|

| Best For | Photo printing, glossy marketing materials | Text documents, archival prints, matte paper |

| Color Quality | Extremely vibrant, brilliant, smooth tones | Excellent color, but slightly less vibrant |

| Durability | Prone to fading and water damage | Highly resistant to fading and water |

| Best Media | Glossy and semi-gloss photo papers | Matte, fine art, and plain office papers |

| Longevity | Shorter lifespan, best for indoor display | Archival quality, lasts for decades |

Ultimately, deciding between these main types of printer ink just comes down to what you print most often. If you need eye-catching, brilliant color, dye delivers. If you need your documents and art to stand the test of time, nothing beats the resilience of pigment.

When you move beyond the familiar cartridges of a home office, you step into a fascinating world of specialty and industrial inks. This is where the magic happens for everything from custom t-shirts to massive billboards. These specialized types of printer ink are engineered for so much more than just color; they're built for performance, durability, and bonding with materials far beyond plain paper.

These heavy-duty inks are designed to fuse with surfaces like fabric, metal, glass, and vinyl—jobs that standard dye or pigment inks simply can't handle. Each type has a unique chemical recipe fine-tuned for a specific purpose, making modern manufacturing and marketing possible.

One of the most interesting specialty inks is sublimation ink. Instead of just drying on a surface, this ink performs a clever little trick: when heated, it skips the liquid phase and turns directly from a solid into a gas. This gas then permanently embeds itself into polyester fibers or specially coated surfaces.

What you get is a design that isn't just sitting on top of the material; it's literally become part of it. This means the image won't crack, peel, or wash out over time. It's in there for good.

When a print absolutely has to survive the elements, solvent inks are the industry's go-to. These are aggressive inks, containing volatile organic compounds (VOCs) that chemically "bite" into surfaces like vinyl and plastic. This creates an incredibly tough, waterproof bond. They are the workhorses behind vehicle wraps, huge outdoor banners, and billboards. For example, the colorful advertisements you see wrapped around city buses are printed using solvent inks to withstand rain, sun, and road grit.

Because of the harsh chemicals and fumes, working with traditional solvent inks requires serious ventilation. To address this, eco-solvent inks were created. While they're still solvent-based, they're derived from refined mineral oils and have a much lower VOC count, making them a safer option for smaller print shops without industrial-grade air filtration.

Many of these specialized inks are essential in fields like large format printing, where resilience and material compatibility are everything.

Key Takeaway: Solvent and eco-solvent inks are all about maximum durability. Their ability to etch into non-porous surfaces like vinyl makes them perfect for graphics that need to withstand sun, rain, and scuffs for years on end.

For printing on almost any surface you can imagine, UV-curable inks provide incredible flexibility. This liquid ink doesn't dry by evaporation. Instead, it’s instantly cured—or hardened—by powerful ultraviolet (UV) light the moment it hits the surface.

This instant curing process means the ink has no time to spread or soak in. The result is exceptionally sharp prints on a huge variety of materials, from wood and glass to acrylic and metal. A practical example is custom-printed phone cases; the vibrant, durable designs are applied with UV inks that cure instantly and bond tightly to the plastic.

Even with all these high-tech niche inks, it's interesting to see that traditional formulas still dominate the broader industry. In fact, oil-based inks are projected to hold a 40.70% share of the $18.58 billion global printing inks market in 2025. Their reliability in large-scale packaging and commercial printing proves they're not going anywhere.

If you're an office manager or IT pro, knowing exactly what ink you have on hand is a lifesaver. It’s about more than just hitting "reorder." The right ink keeps your printers healthy, your print quality sharp, and turns your supply closet into a potential asset. Using the wrong one? That’s a fast track to clogged printheads and expensive repairs.

Luckily, figuring out the different types of printer ink you have is usually pretty simple. The original box is your best friend. Manufacturers often use specific brand names that give the game away.

Take Epson's "DURABrite" ink, for example—that's their well-known pigment-based formula built for durability. On the other hand, HP's "Vivera" line is a good indicator that you’re dealing with their vibrant dye-based inks. A quick glance at the packaging can tell you everything.

What if the box was tossed out months ago? No problem. The printer itself is your next clue.

Find the printer’s model number, which is almost always on the front or back of the machine. A quick web search for "[Your Printer Model] ink type" will bring up the specs you need. The user manual is also a reliable source, listing the exact cartridge models and ink technology required.

Pro Tip: Set up a simple spreadsheet tracking your printers and their specific ink cartridge numbers and types. For example, a row could read: "HP OfficeJet Pro 9015 | HP 962 Cartridges | Pigment-Based (All Colors)". It's a small bit of upfront work that saves a ton of time and prevents costly mix-ups later, especially in an office juggling multiple machines.

Once you know what you've got, how you store it is just as crucial. Think of ink cartridges like fresh produce—improper storage can ruin them long before they ever see a printer. A brand-new cartridge can be rendered useless by sitting in the wrong environment.

To keep your ink in top condition, just follow a few simple rules. These steps protect your investment and are absolutely critical if you ever plan to sell your surplus stock. A poorly stored cartridge has zero resale value.

Most importantly, keep an eye on those expiration dates. Old ink can separate and clog printheads, turning that surplus supply from a hidden asset into a major headache. This is especially true if you're looking to sell unused cartridges. To get the best offer, your inventory needs to be clean and well-organized. You can see how to best prepare your items by checking out these instructions on submitting images of your surplus toner.

That dusty shelf in your supply closet, piled high with unused printer ink? It’s not just clutter—it’s cash waiting to be claimed. Businesses often find themselves with surplus genuine cartridges after upgrading printers, changing suppliers, or even just downsizing. Instead of letting that inventory expire and turn into e-waste, you can sell it.

The whole process is a lot easier than you might think. You can quickly turn those depreciating assets back into working capital for your business. It's a win-win: good for your budget and even better for the environment.

Not all surplus ink will fetch a good price. To get top dollar, your cartridges need to tick a few specific boxes that buyers always look for. These standards are in place to make sure the next person gets a product that works as flawlessly as a brand-new one.

First and foremost, it’s all about authenticity. Buyers are only interested in genuine OEM (Original Equipment Manufacturer) cartridges—the ones made by brands like HP, Epson, or Canon. Unfortunately, remanufactured or third-party compatible cartridges won't make the cut.

The condition of the packaging is just as crucial. The box must be new, unopened, and factory-sealed. Any damage like rips, deep dents, or water stains will lower its value. For example, a box with a crushed corner or a peeled-off label will fetch a much lower price than a pristine one. For inkjet cartridges, the expiration date is key; most buyback programs require at least a year left on the clock.

Think of it this way: OEM status, pristine packaging, and a solid expiration date are the three pillars that determine how much your surplus ink is worth.

Turning your unused ink into cash is a simple, three-step process built for people who don't have time to waste. No back-and-forth haggling, no creating complicated online listings.

This streamlined approach takes all the hassle out of finding a buyer. If you'd prefer to manage the sale yourself, you could also list your inventory on a platform like the Clearance Central Marketplace.

The demand for printer ink is always there, and it's growing. The global market was valued at USD 21.8 billion in 2025 and is expected to climb toward USD 39.0 billion by 2035. This isn't just a corporate trend; the explosion in remote work caused a 19% spike in demand across North America, Europe, and Asia. Knowing the different types of printer ink and their value helps you see what's really sitting in your supply closet.

By selling your surplus, you’re doing more than just recovering some money. You're taking part in a circular economy—a smart and simple way to declutter your office, boost your bottom line, and make an environmentally sound choice by keeping perfectly good products out of the landfill.

Selling your extra genuine ink cartridges isn't just about making a quick buck—it’s a savvy strategic decision. Think about it: clearing out that supply closet immediately frees up valuable shelf space and, more importantly, eliminates the risk of those cartridges expiring and becoming worthless e-waste.

It's a proactive move that directly boosts your bottom line. You're recovering money that would otherwise vanish once the ink passes its expiration date, effectively turning a depreciating asset back into cash you can use.

On top of the financial benefits, it's an incredibly responsible choice. Instead of letting perfectly good cartridges end up in a landfill, you're putting them back into circulation for another business to use. This is a practical step toward a more sustainable, circular economy where we get the most out of every resource.

Simply put, it’s a clear win for your budget, your operations, and the environment. Taking a few minutes to see what's collecting dust in your supply closet can unlock value you probably forgot you had.

This sustainable thinking is catching on everywhere. For example, water-based inks are becoming hugely popular in packaging and textiles as environmental regulations get stricter. A practical example is the shift to water-based inks for printing on cardboard food packaging to reduce chemical contamination risks. This shift is a big reason why the printing inks market is projected to grow from an estimated US$24.33 billion in 2025 to US$31.58 billion by 2032. You can read more about the growing printing inks market to see the bigger picture.

By monetizing surplus supplies, your business not only recoups costs but also actively participates in a larger movement toward reducing industrial waste and promoting resource efficiency.

Every unopened box of genuine printer ink sitting on your shelf is a missed opportunity. Businesses change, printers get upgraded, and needs shift, often leaving behind perfectly good, high-value inventory. These aren't just sunk costs; they're assets you can recover.

The good news is that the selling process is straightforward, turning a dreaded clean-out into a genuinely profitable task. Here’s what it means for your company:

The first step is figuring out what you actually have by understanding the different types of printer ink in your inventory. Once you know what’s on the shelf, you can quickly find out its resale value and turn it into cash before it expires. It’s a simple, smart strategy for any business looking to operate more efficiently.

Even after you get a handle on the different types of printer ink, a few common questions always seem to pop up. Let's tackle some of the ones we hear most often from businesses trying to manage their printing supplies.

In a word: no. This is one of the most important things to remember. Pouring dye-based ink into a printer built for pigment ink (or vice-versa) is a recipe for disaster.

Think of it like putting diesel in a gasoline engine. The chemical makeups are totally different, and trying to mix them can lead to clogged printheads, awful-looking prints, and even permanent damage to your machine. Always stick with the specific ink your printer’s manufacturer recommends.

Wondering if those extra cartridges collecting dust are worth anything? Their value really boils down to three key things. For a buyback company to even consider them, they need to check these boxes:

Generally, ink for popular, current-model business printers will get you the best price. The easiest way to find out what you've got is to send your list over for a quick quote.

Key Insight: Treat your extra cartridges like any other business asset. Their value is at its peak when they are genuine, in perfect condition, and have plenty of time before they expire. If you wait too long, that valuable asset can quickly become worthless e-waste.

This is a fundamental question, and the answer lies in what they're made of and how they work. The two are definitely not interchangeable.

Ink cartridges are for inkjet printers and are filled with liquid—either a dye or pigment solution. The printer sprays thousands of microscopic droplets of this liquid directly onto the paper to create the image. A practical example is a home office printer used for printing school assignments and family photos.

Toner cartridges are for laser printers and contain a very fine, dry powder. A laser printer uses a combination of static electricity and heat to melt this powder and fuse it onto the paper, which is a completely different process. For instance, the large, high-speed machine in a corporate office that prints hundreds of black-and-white reports daily uses toner.

Ready to turn your surplus printer supplies into cash? At Toner Connect, we make it easy to get a competitive offer for your unused OEM ink and toner. Submit your list today and see how much you can earn.