If your printer is producing faded, streaked, or uneven prints, you may need a new drum. Understanding printer drum replacement and toner buyback can help you solve print issues and save money on unused supplies. This guide explains how to diagnose drum problems, replace the unit safely, and take advantage of toner buyback programs to turn extra cartridges into cash.

The good news? Cleaning printer rollers is quick, easy, and usually fixes the problem within minutes. Even better, this is the perfect time to sort out unused or surplus toner you may have lying around—and sell excess toner inventory for fast cash.

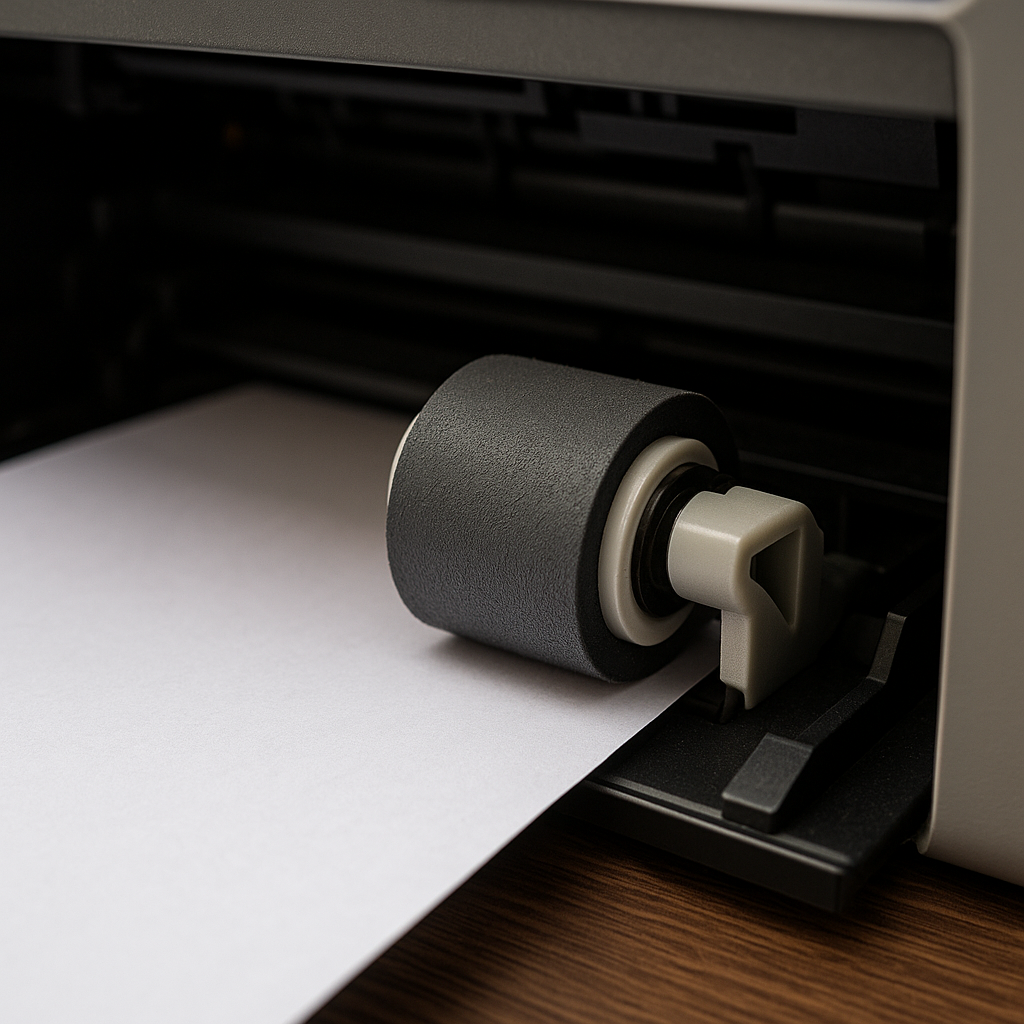

Just like car tires need traction, printer rollers need grip. When they’re new, they can easily pick up a single sheet and move it cleanly through the print path. After thousands of pages, though, dust and grime create a slick layer that makes rollers slip.

Paper never leaves the tray

Printer grabs multiple sheets at once

Pages print crooked

Frequent unexplained jams

Repeating smudges or roller marks

These symptoms often mimic expensive mechanical failures—but most are fixed with a 5-minute cleaning.

Pulls paper from the tray.

Symptom: Printer tries to print but paper doesn’t move.

Push paper through the internal path.

Symptom: Crooked or skewed prints.

Stops multiple sheets from feeding.

Symptom: Printer grabs a stack of pages at once.

Knowing which roller causes which issue makes troubleshooting fast and simple.

It’s easy to mistake the symptoms of dirty rollers for something much worse. For instance, have you ever gotten a paper jam error even though the paper hasn’t budged from the tray? That’s a classic sign of a pickup roller that’s lost its grip and is just spinning in place.

Another tell-tale sign is skewed or crooked prints. This often happens when grime has built up unevenly on the feed rollers, causing one side to pull the paper faster than the other. A practical example would be printing an invoice where the company logo and address in the header are noticeably tilted on the page.

This simple maintenance task is so critical that it supports a massive global market. Valued at around $412 million in 2024, the printer cleaning supplies industry is projected to grow significantly. That number alone shows just how common and important this routine fix is. You can discover more insights about the printer maintenance market and its growth trends.

Never rely on the power button. Laser printers must cool 15–20 minutes—the fuser reaches over 400°F.

Inkjet printers: Lift the scanner bed; rollers are visible above the tray.

Laser printers: Remove the toner and lower tray; primary rollers sit just above the cavity.

Avoid isopropyl alcohol for routine cleaning—it dries rubber and reduces lifespan.

Best cleaning agents:

Distilled water (safe for routine cleaning)

Rubber roller cleaner (restores grip on slick rollers)

Lint-free microfiber cloths

Long-handled cotton swabs (for tight spots)

Paper towels or cotton balls leave fibers behind—never use them.

This isn’t just some niche product; proper maintenance is big business. The global market for rubber roller cleaners was valued at around $1.14 billion in 2024. That’s a lot of people trying to keep their printers running smoothly. If you’re curious about the industry behind these products, you can explore detailed insights on the rubber roller cleaner market on marketresearchfuture.com.

Dampen your cloth lightly—never pour liquid directly on rollers.

Press the cloth against the roller surface.

Rotate the roller by hand to clean the entire circumference.

Repeat until no residue appears on the cloth.

Let rollers air-dry at least 10–15 minutes.

This simple method resolves the majority of roller-related problems.

So, you’ve cleaned every roller you can see, but your printer is still jamming or misfeeding. It’s time to play detective. Get a flashlight and take a really close look deep inside the paper path. You might be surprised to find a small, hidden roller you missed on the first pass.

This level of care isn’t just for your desktop machine. Think about industrial printing, where specialized anilox rollers require meticulous cleaning to ensure perfect ink transfer. Some large-scale print shops have protocols to clean them after every single shift to maintain quality. You can learn more about industrial roller maintenance strategies to appreciate how vital this is. For your printer at home, it’s a great reminder that frequent, gentle cleaning is always a better strategy than one aggressive deep clean when things go wrong.

Cleaning won’t fix rollers that are physically deteriorated. Replace them if you notice:

Shiny or glazed appearance

Visible cracks

Flat spots

A slippery texture

Rubber flaking or peeling

Roller replacement costs are low—often under $20—and prevent unnecessary printer downtime.

There’s no single answer here—it really just depends on how much you print. The beast of a printer in a busy office churning out hundreds of pages a day needs a lot more attention than the one you use at home for the occasional recipe or concert ticket.

A great rule of thumb is to give the rollers a quick look-over every time you swap out a toner or ink cartridge. For example, when you replace the black toner on your Dell laser printer, take an extra 60 seconds to wipe down the pickup roller that’s now easily accessible. This simple habit turns a reactive fix into proactive maintenance, letting you spot wear and tear before it grinds everything to a halt.

For businesses where printing is mission-critical, understanding these cycles is key. In fact, many toner and ink dealers offer programs to help you build a maintenance schedule that lines up perfectly with your supply needs.

Ultimately, the printer will tell you what it needs. If you’ve cleaned the rollers properly and you’re still getting those frustrating misfeeds, that’s your cue. The rubber is done. It’s time to order a replacement.

While maintaining your printer, you may notice unopened toner boxes or surplus supplies in storage. Instead of letting them expire or take up space, turn them into money.

Businesses accumulate unused toner when:

Printers are upgraded

Offices close or relocate

IT departments switch models

Over-ordering or vendor changes occur

This creates valuable excess toner inventory—and Toner Connect buys it for top dollar.

Toner Connect specializes in purchasing:

OEM toner

Unopened toner cartridges

Overstock & surplus toner

Bulk toner lots

Liquidation toner collections

Unused corporate inventory

You get:

Fast cash for toner cartridges

Free insured shipping

Same-day payment

The highest online buyback prices

No minimums — no hassles

At Toner Connect LLC, we help businesses turn their surplus printer supplies into cash. If you have new, unopened OEM toner and ink you no longer need, get a fast, competitive quote and enjoy free, insured shipping. Visit us at https://tonerconnect.net to see how easy it is to declutter your storage and recover value.